Model No.︰Ultramid B3EG6

Brand Name︰Ultramid PA6

Country of Origin︰Germany

Unit Price︰-

Minimum Order︰25 KG

Nylon 6.

| Type | Color No. | Materials No. | Origin | Available |

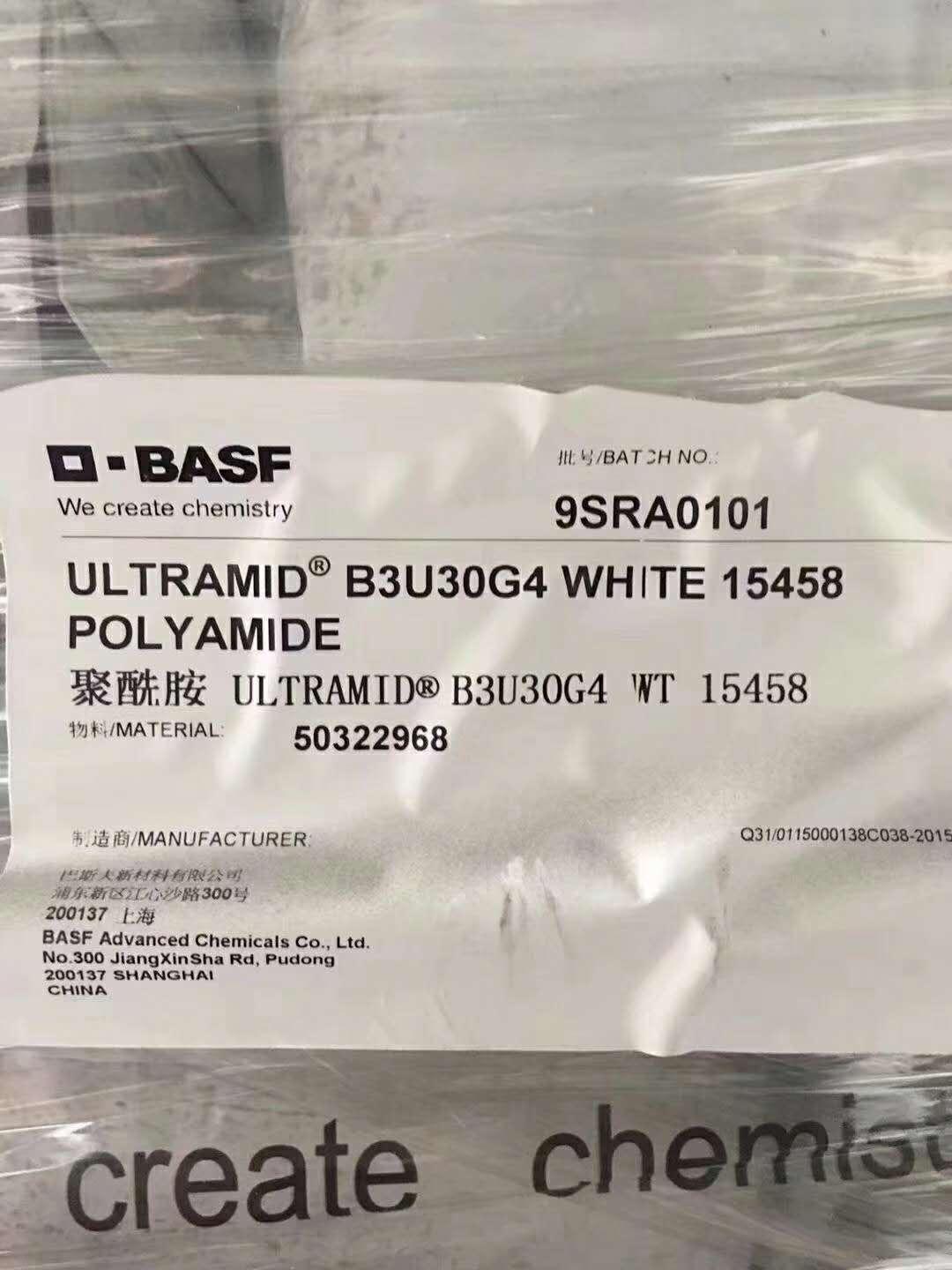

| Ultramid B3U30G4 | White 15458 ** | 50322968 | China | 5,500 kg |

|

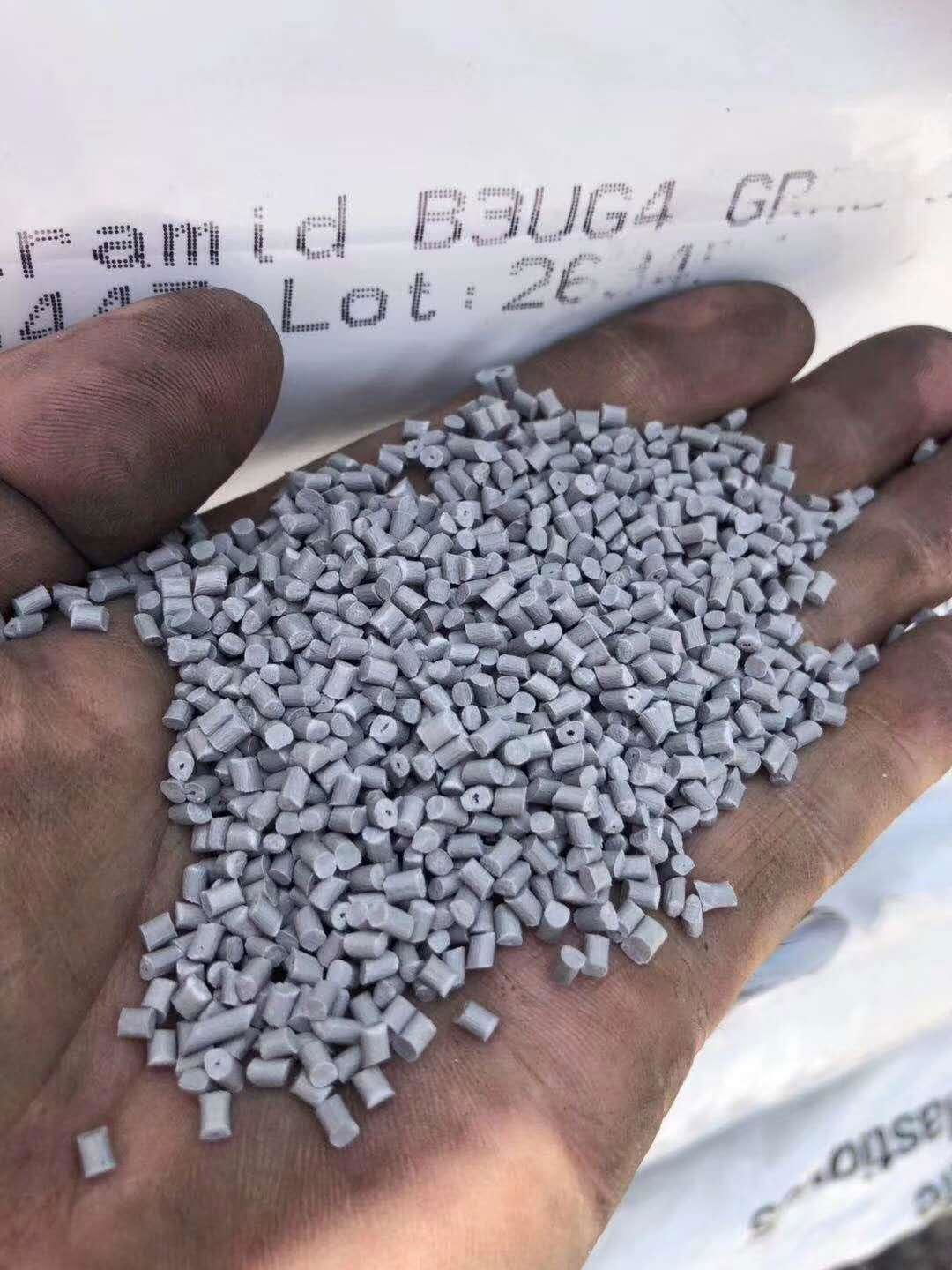

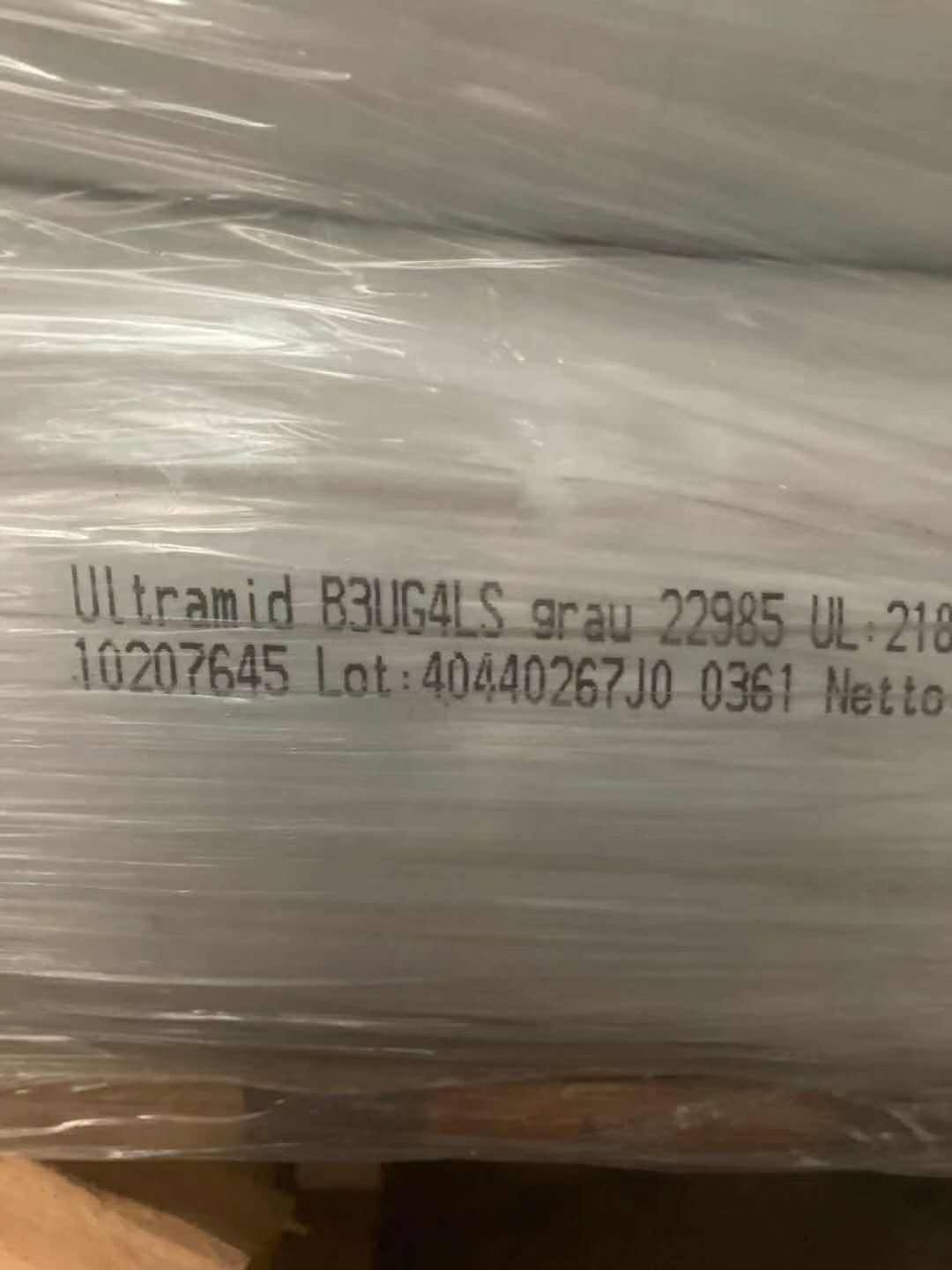

Ultramid B3UG4 Ultramid B3UG4 LS Ultramid B3UG6 |

GR32125 GRAU 22958 ** White |

Germany |

625 kg 300 kg 100 kg |

|

|

|

|

|||

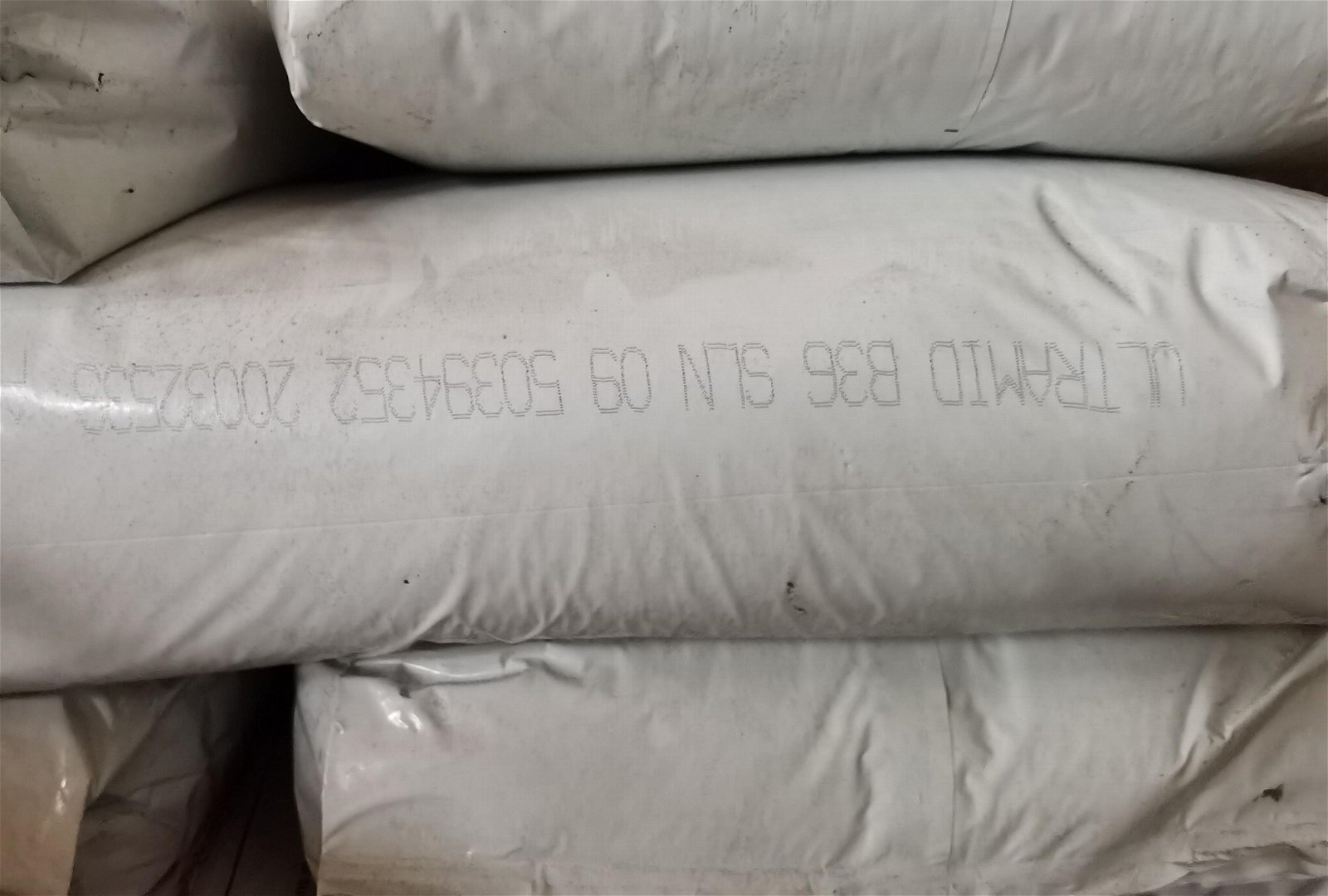

| Ultramid B36 SLN | Natural 09 | 56954475 | USA | 900 kg |

|

Ultramid B3GK24 Ultramid KR4450 |

UN GREY |

50026500 ** |

China |

50 kg 600 kg |

|

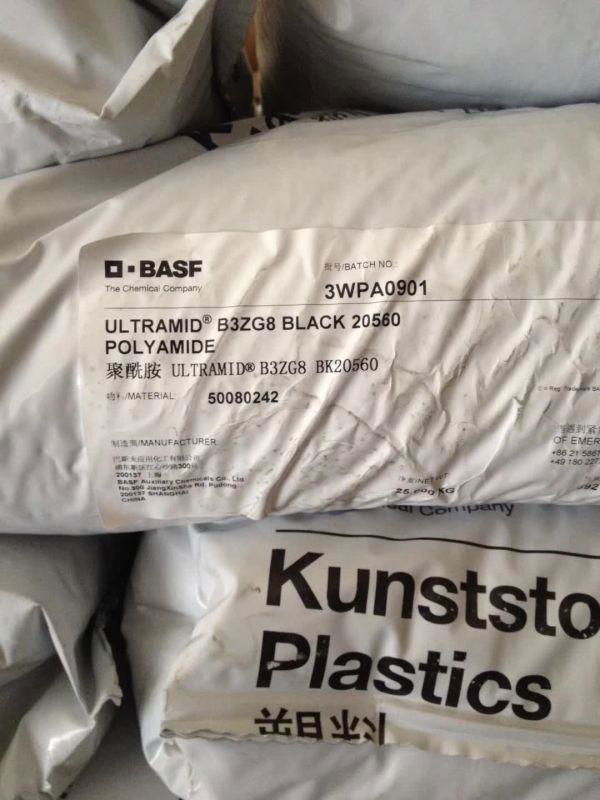

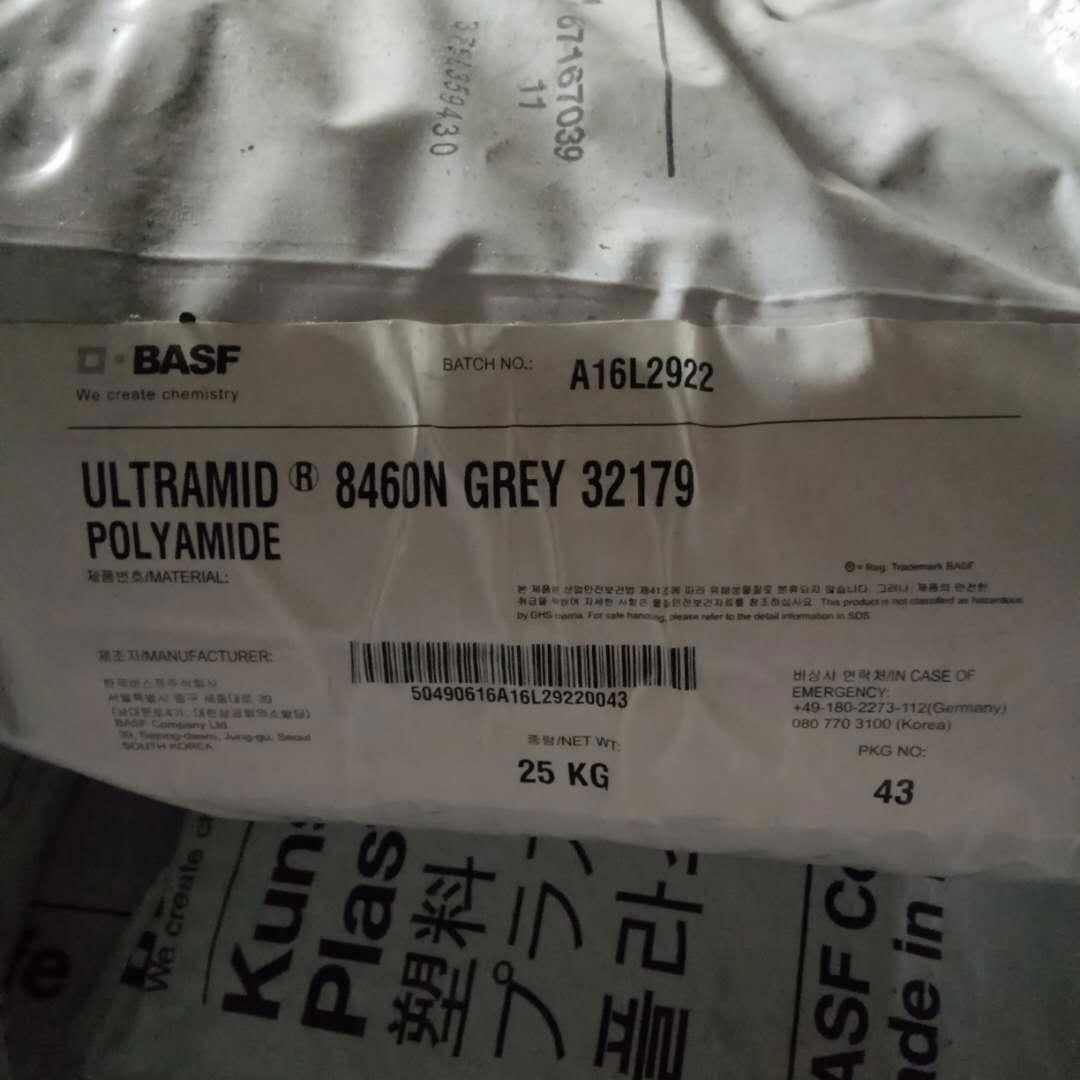

Ultramid B3ZG3 Ultramid B3ZG6 Ultramid B3ZG8 Ultramid B3ZG8 HB |

BK00564 Uncolored BK20560 BK23309 |

- 50079712 54333411 50642269 |

China |

500 kg 300 kg on request 100 kg |

| Ultramid B3U Q721 |

WT15477 ** WT-0240-A ** |

50551257 50521401 |

China |

1,000 kg 5,000 kg |

|

Ultramid B3UM4 Ultramid B3UM6 Ultramid B3M6 |

GREY 32149 Black ** GREY Q94 22319 ** |

** 50158358 56593121 |

Germany Malaysia China |

1,100 kg 600 kg 1,300 kg |

| Ultramid B3WGM24 | BK23228 | 55311103 | Malaysia | 300 kg |

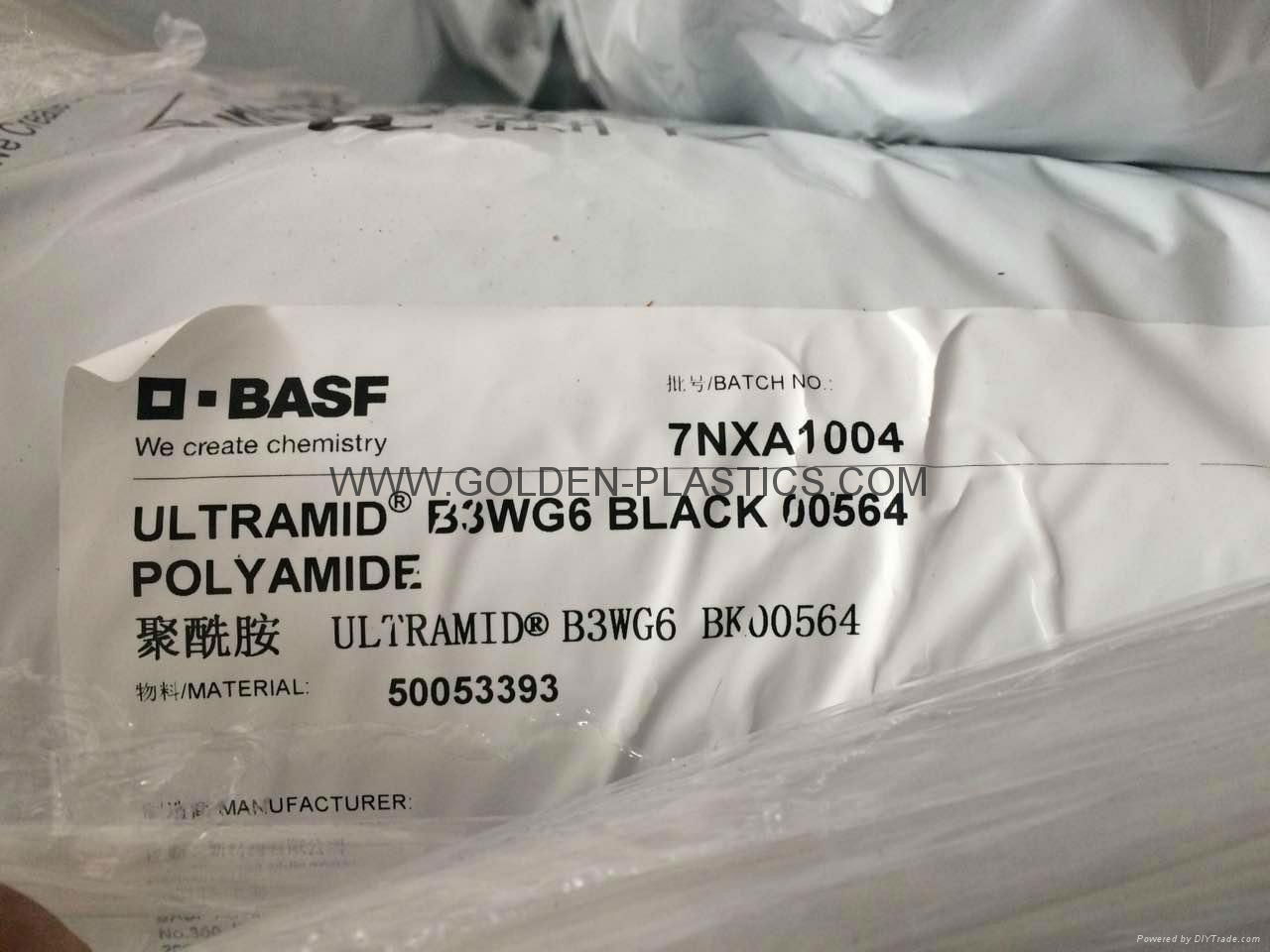

| Ultramid B3WG6 |

BK00564 |

5007019 |

China |

1,500 kg |

|

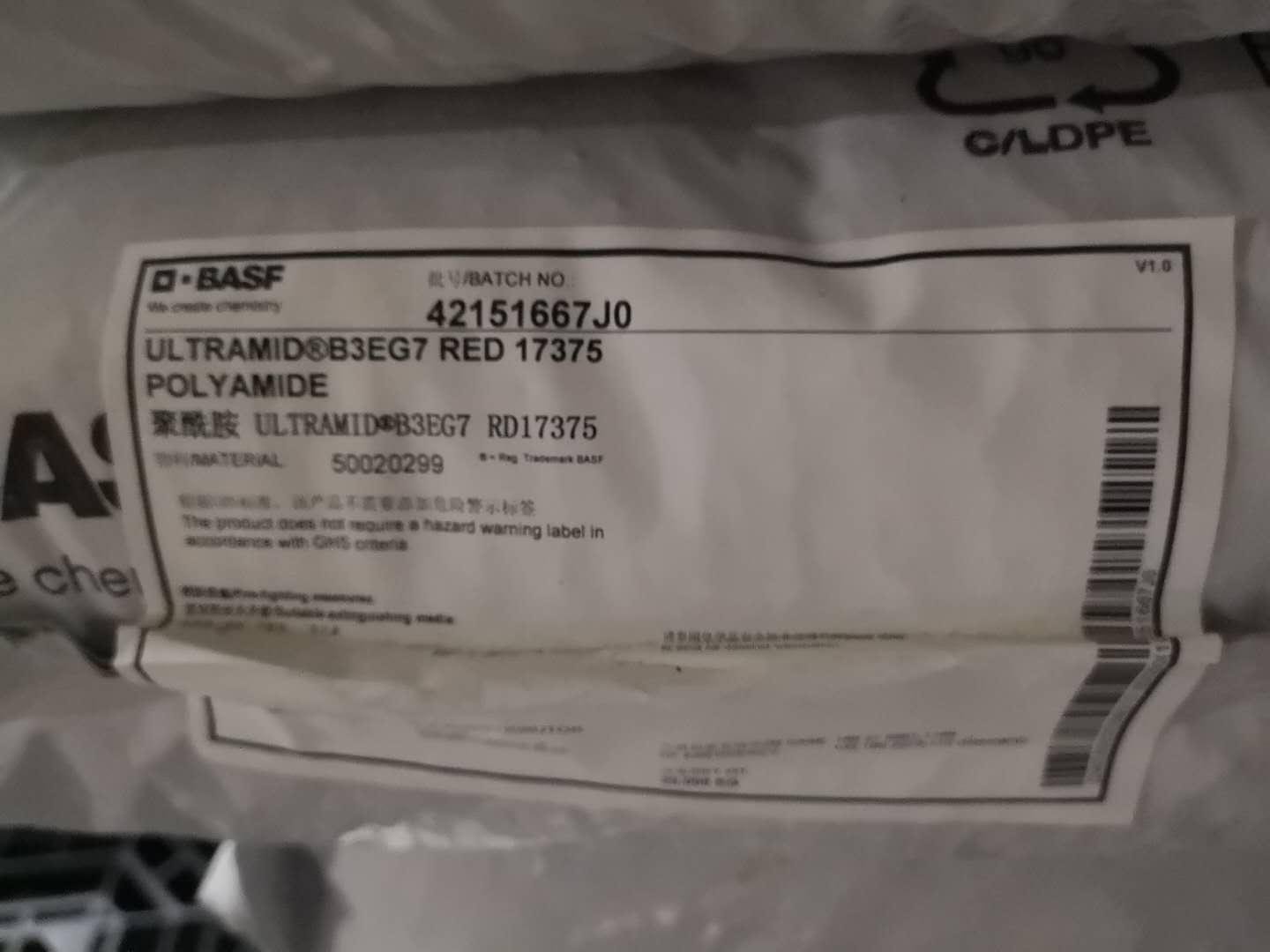

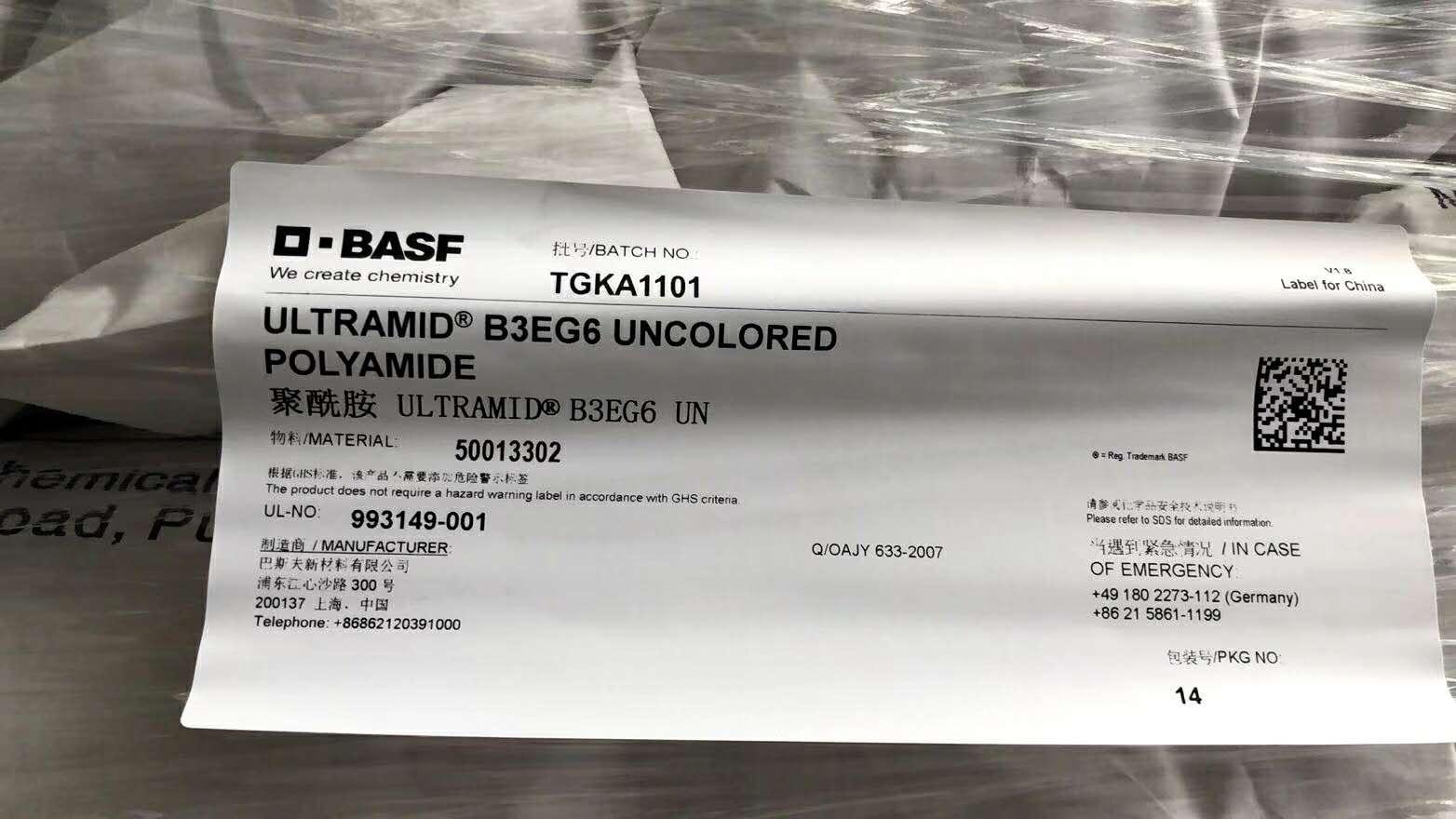

Ultramid B3EG3 Ultramid B3EG6 Ultramid B3EG7 |

Uncolored BK00564/UN Uncolored |

50070353 52570421/50081427 50039561 |

China/Malaysia |

100 kg 200 kg 500 kg |

|

Ultramid B3WG6 Ultramid B3WG6 R01 Ultramid B3WG6 GP |

Black Q780 Uncolored BK23210 |

50322972 53320068 50635068 |

China |

500 kg 300 kg 200 kg |

| Ultramid B3WG7 |

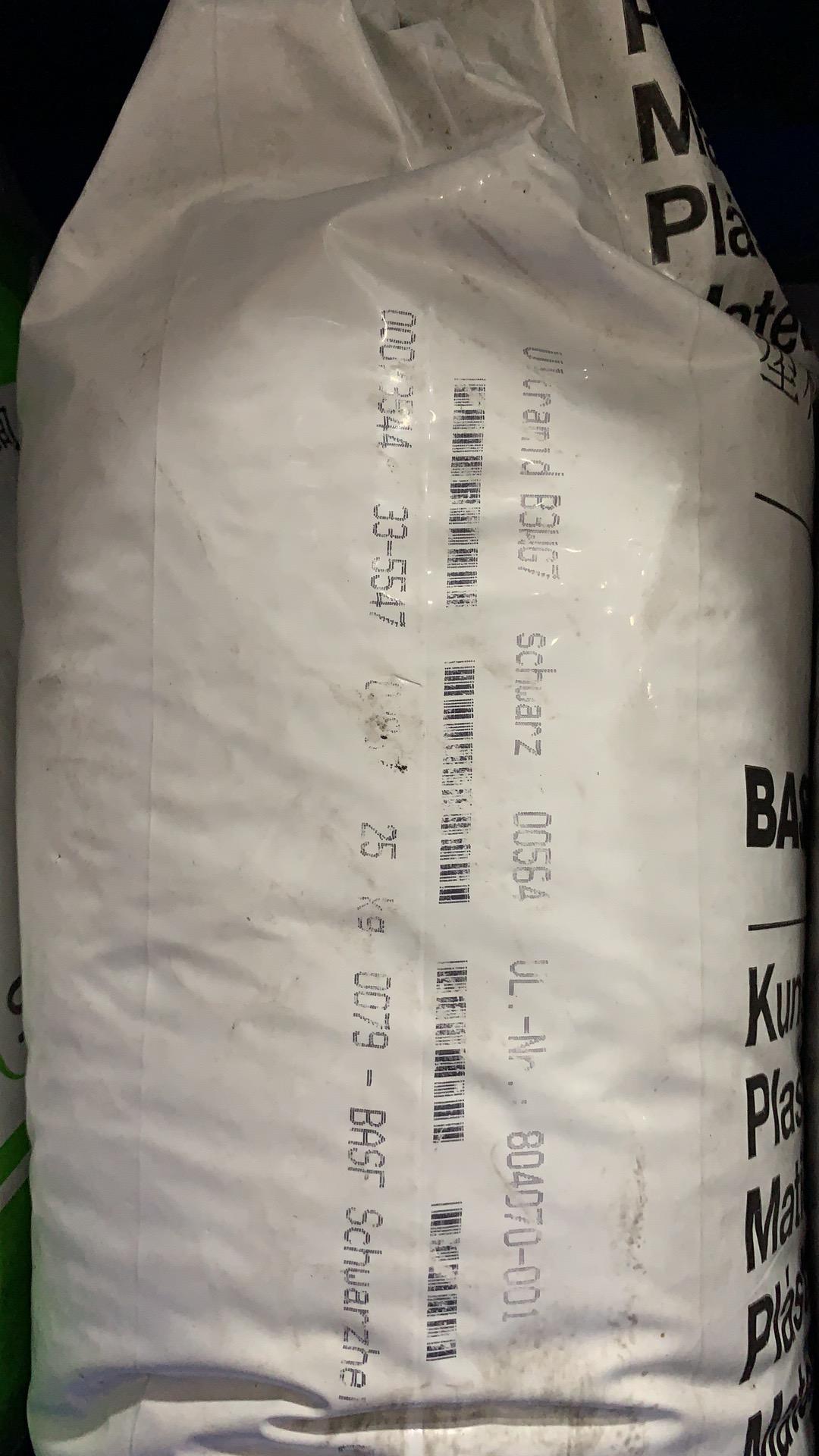

Schwarz 00564 BK20560 Q17 |

00073544 50095687 |

Germany China |

275 kg 500 kg |

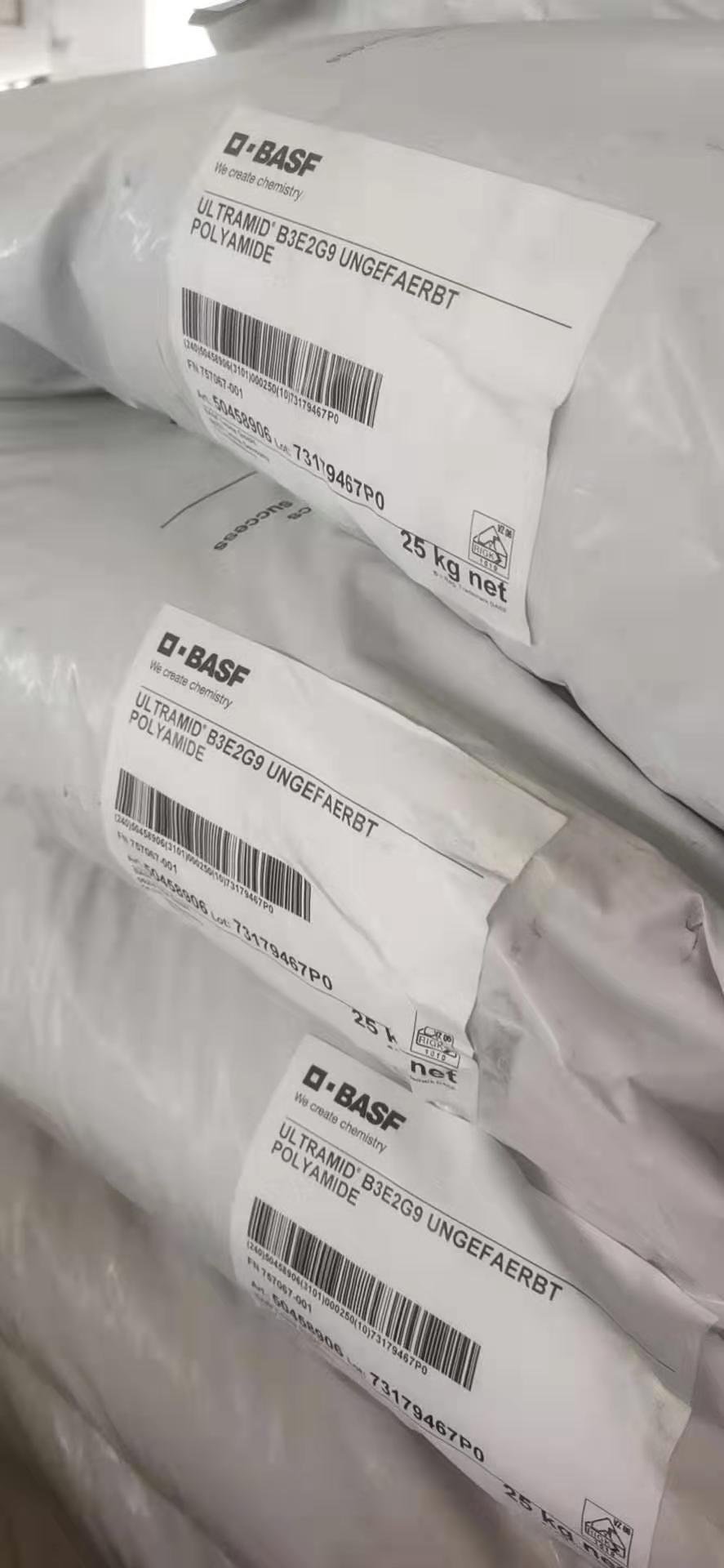

| Ultramid B3E2G9 | UN ** | 50458906 | Germany | 100 kg |

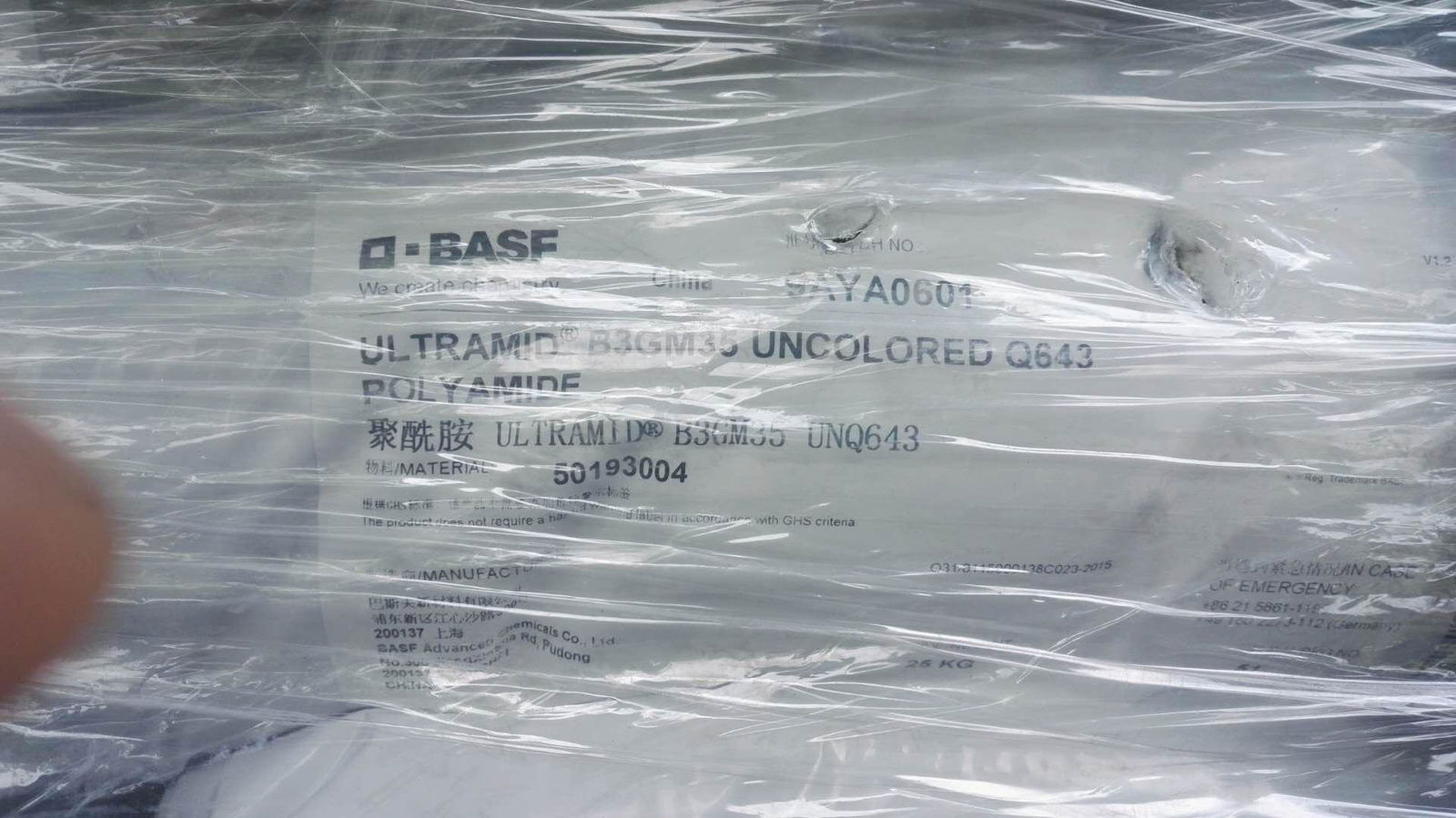

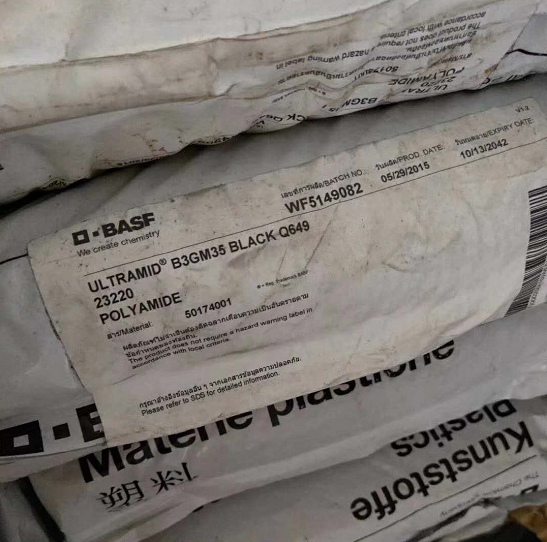

| Ultramid B3GM35 Q649 | BLACK 23220 | 50174001 ** | Germany | 100 kg |

| Ultramid B3WG10 R01 | Black 00564 | 50426548 ** | China | 200 kg |

| Ultramid B3WG12 HSP | Black 23228 | 50473989 | China | 500 kg |

|

Ultramid B3S Ultramid B3S Ultramid B3S R01 |

Uncolored GERY32140 WS 111 |

50373605 50373477 ** 53292070 ** |

China |

50 kg 3,000 kg 100 kg |

|

**Notes: Our inventory list changes every month, Marked **,This is a spot buy one time deal & not repeatable…we got this from a molder who had excess inventory. More order and datasheet/msds and other certificate and packaging pics,Please send e-mail to : x.g.chiang@gmail.com |

Payment Terms︰ T/T

Packing︰ 25KG/BAG

Lead Time︰ 5 DAYS